You have many options when you want to make your factory better. The tapping machine business is getting bigger.

The market for tapping drilling machines was worth $2.5 billion in 2022.

Experts think it will be $3.8 billion by 2030.

This growth happens because of new technology and higher rules in making things. Many factories now want machines with smart features that follow strict rules.

Trend | Description |

CNC integration and IoT connectivity help work faster and better. | |

Regulatory standards | Safety and environmental rules need new machines. |

Focus on Industry 4.0 | Smart factories use advanced tapping machines in their work lines. |

Think about how much you need to make. If you make a lot, you need a machine that works fast and does not make mistakes.

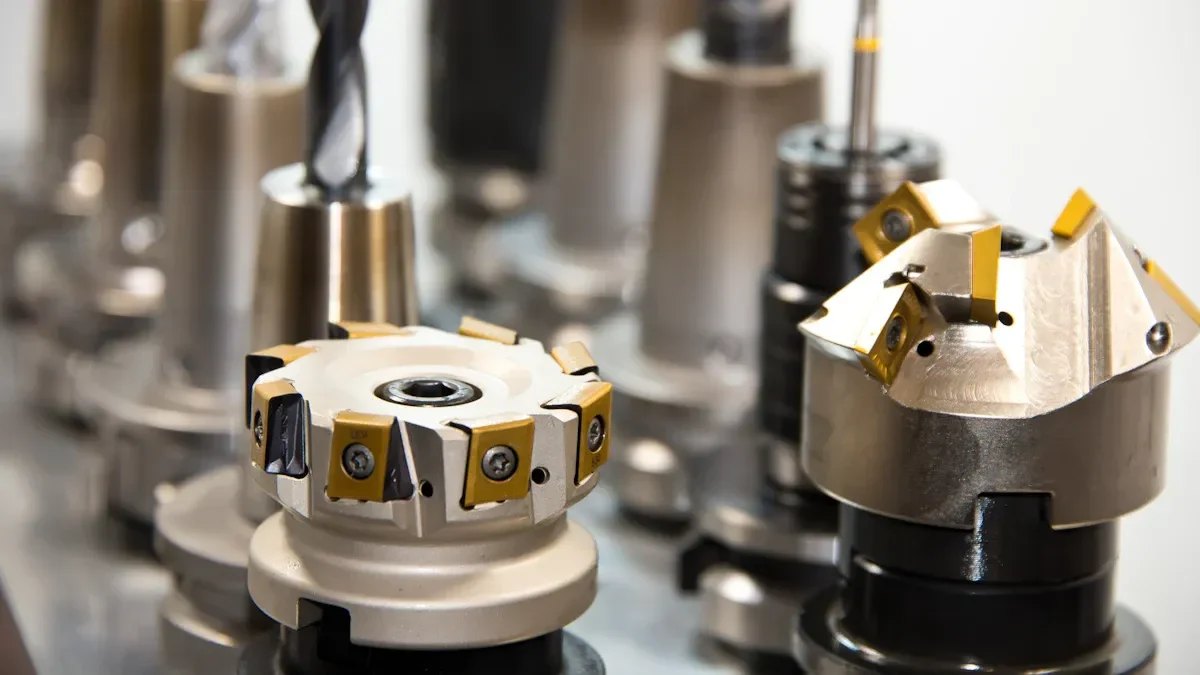

Make sure the machine works with your metals. It should be able to use steel or aluminum.

Look at how much the machine does by itself. Machines that do everything for you save time and stop mistakes. They are good for big jobs.

Pay attention to how much energy the machine uses. New machines can use 30% less energy. This helps the planet and saves you money.

Think about how easy it is to fix the machine. Some machines have smart sensors. These sensors tell you about problems before they get bad. This helps your work go well.

Think about how many parts you want to make. If you need to make lots of parts, pick a tapping machine for high volume. Many factories use machines with IoT sensors and machine learning now. These features help you watch data and know when to fix the machine. When you make more parts, you need fast machines with few mistakes. In aerospace and automotive, high-precision tapping machines are popular. They help meet strict quality rules.

Check what materials you want to use. Tapping machines work with many metals. Common choices are:

Steel

Stainless Steel

Aluminum

Brass

Copper

Cast Iron

If you use many materials, choose a machine for all of them. Some machines work better with hard metals. Others are good for softer metals.

You can pick different automation levels. The right level saves time and lowers mistakes. Here is a simple chart:

Level of Automation | Description |

Manual Tapping Machines | You use your hands for all steps. |

You use your hands for all steps. | Some steps are automatic, but you still help. |

Fully Automatic Tapping Machines | The machine works by itself most of the time. |

Factories that make lots of parts use fully automatic machines. This helps them work faster.

Energy costs are important for every factory. New tapping machines use less energy because of digital controls. You can save up to 30% on energy with better models. Makers now build greener machines to follow rules and save money.

Pick a tapping machine that is easy to care for. Machines with smart sensors warn you before problems start. This helps you stop long breaks and keeps work going. Taking care of your machine helps it last longer.

Compare the price and the cost over time. Here is a chart:

Model Type | Price Range |

Entry-Level Manual Models | $900–$2,500 |

Mid-Range Semi-Automatic | $2,500–$5,000 |

Automatic / Inline Systems | $6,000–$15,000+ |

Other costs are energy, tape, and how long the machine lasts. Most machines work well for 5–10 years with good care.

Tip: Make sure the features fit your needs. A cheaper machine may cost more later for repairs or energy.

Electric models help your factory work better. These machines keep speed, feed, and torque steady. You get the same threads every time. Electric tapping machines stop assembly problems. They make products more reliable. Automation makes tapping cycles shorter. You can make more parts quickly. Many factories in Japan use electric models. They are good for making lots of parts. These machines have dust-proof designs. They also have automatic tapping features.

Key Features | |

Threading from any angle | Making threads inside many materials |

Dust proof design | Making lots of parts |

Automatic tapping options | Fixing broken threads |

Adjustable servo motor for variable speeds | Using different tap sizes |

Compact size with articulated arm | Good for many factory jobs |

| Tip: Electric models work with metals and plastics. You can use them for fixing or making new things.

Servo-driven machines give you very exact results. You control speed and depth with smart systems. These machines use encoders for perfect timing. This stops pitch errors and broken taps. You get instant reversal to keep blind holes safe. Factories in Japan and other places use servo-driven models. They are used for aerospace and car work.

Function | Hydraulic Limitation | |

Rigid Tapping | Valve lag causes pitch error | Perfect timing with encoders |

Reversal | Slow (tap can break) | Instant (safe for blind holes) |

Peck Drilling | Position moves, slow cycle | Exact depth, fast cycle |

Control | Reacts to pressure | Uses smart systems |

Multi-directional tapping machines tap threads at many angles. You can drill and ream small or big holes. These machines help you work faster and better. You can use CNC machines for harder jobs. This saves time and money. Multi-directional models are liked by factories. They are good for flexible and strong work.

You work faster by using CNC machines for tough jobs.

Operators make fewer mistakes and break fewer taps.

You make things quicker and spend less on machines.

Combination machines drill and tap at once. You can make more parts and handle less by hand. Automation means fewer mistakes and less waiting. You get better accuracy, so you fix less. Many factories use these machines for cars, electronics, planes, and furniture.

Benefit | Description |

| Simultaneous Operations | The machine drills and taps at the same time. You make more parts faster. |

Reduced Manual Handling | Automation means you do less by hand. There are fewer mistakes and less waiting. |

Improved Accuracy | The machine is very exact. Your products are better and need less fixing. |

| Note: Japanese makers build small, fast combination machines for the world.

Model A is a top pick for many factories in 2026. It gives you good speed, safety, and flexibility. You can use it for small or big jobs. You change spindle speed and torque for different materials. The digital display helps you set up fast. Safety interlocks keep your team safe while working. Model A works for batch or nonstop production.

Feature/Specification | Description |

Spindle Speed Range | You can change speeds from 50 to 3000 RPM. This helps with different materials and tap sizes. |

Torque Output | It has high torque for hard materials. Overload protection keeps the machine safe. |

Stroke Length | You can make threads from 50 mm to 300 mm deep. |

Feed Rate Control | Precision controls stop cross-threading. They help make a smooth finish. |

Automation Level | You can use push-buttons or full PLC/CNC controls. |

Safety Interlocks | Emergency stop and guard sensors keep workers safe. |

Digital Display or HMI | You can change settings and check problems quickly. |

Advantages:

You make parts faster than by hand.

You get better threads and less waste.

You spend less on labor over time.

You make the workplace safer.

You can do bigger jobs when needed.

Disadvantages:

You pay more at first, especially for CNC models.

You need to teach your team how to use and fix it.

You must do regular care as the system is complex.

You may not save money if you only do tiny jobs.

| Tip: Model A is best for factories that want to grow and need a reliable, flexible tapping machine.

Model B uses servo-driven technology in your factory. You control speed and depth very well. Smart sensors stop mistakes before they happen. Instant tap reversal protects taps in blind holes. Model B is good for aerospace, automotive, and electronics factories. It works with hard metals and tight rules.

Key Features:

Servo motor with encoder gives exact speed and position.

Instant tap reversal helps with blind holes.

Smart sensors find errors early.

Touchscreen controls make setup easy.

Modular design makes fixing fast.

Pros:

You get high accuracy and repeat results.

You break fewer taps and have less downtime.

You switch jobs quickly.

You save energy with smart motors.

Cons:

You pay more for advanced features.

You need skilled workers for best results.

You may find it too hard for simple jobs.

| Note: Pick Model B if you need top precision and work with many kinds of parts.

Model C lets you tap threads at many angles. You do not need to move your workpiece. It works in manual or automatic mode. The compact design fits in small spaces. Model C is liked in furniture, appliance, and custom metal shops.

Key Features:

Multi-angle tapping head lets you tap at different angles.

Manual and automatic modes give you choices.

Small frame fits tight spaces.

Quick-change tap holders save time.

Built-in LED lights help you see your work.

Pros:

You save time by tapping at many angles in one setup.

You make fewer mistakes moving parts between machines.

You fit the machine in small work areas.

Cons:

You may not get top speed for straight jobs.

You need to check alignment for best results.

You may need extra training for multi-angle jobs.

| Tip: Model C is smart for shops that work with custom or odd-shaped parts.

Model D drills and taps in one cycle. You finish parts faster and handle less by hand. It has a strong frame and fast spindle. You get automatic tool change and part ejection. Model D is good for big factories in automotive, electronics, and furniture.

Key Features:

Drilling and tapping happen in one pass.

High-speed spindle goes up to 4000 RPM.

Automatic tool changer saves time.

Conveyor moves finished parts out.

PLC gives full automation.

Pros:

You make more parts with fewer steps.

You have fewer operator mistakes.

You get steady quality in big batches.

Cons:

You pay more at the start.

You need to check tool wear often.

You may not need all features for small jobs.

| Note: Model D is best for factories that want to automate and make more parts.

Each tapping machine model fits a different kind of factory. Think about what you need for speed, accuracy, and automation before you pick.

You might want to see how the models are different. The table below lists important features from top brands. Some machines have CNC controls and robotic arms. Many models have automation to help you work faster. A few machines are best for making lots of parts. Other machines are better for small shops or special jobs.

You need to pick the right machine for your work. Here are some common ways people use these machines:

Big factories use robotic and CNC machines to make many parts.

Small shops choose manual or small electric machines for repairs and custom work.

Electronics companies need automated threading for tiny pieces.

Furniture and appliance shops use multi-angle machines for odd shapes.

Assembly lines like machines with fast tool changes and conveyors.

There is a tapping machine for every kind of job, from simple fixes to big factory work.

You need to start by looking at your factory’s daily work. Think about how many parts you make each day. Check the types of materials you use, like steel, aluminum, or plastic. Decide if you need high precision for your products. Write down your budget and how much you want to spend over time. You should also think about how much space you have for new equipment.

Here is a table to help you organize your needs:

| Criteria | Description |

Production Volume | How many parts you make each day or week. |

Material Compatibility | Types of materials you use, such as metals or plastics. |

Precision and Accuracy | How exact your threads need to be for your products. |

Budget and Cost-Effectiveness | How much you want to spend now and in the future, including care and repairs. |

Tip: Write down your answers for each point. This will help you later when you compare machines.

After you know your needs, you can match them to machine features. Look for machines that fit your production volume. Make sure the machine works with your materials. Check if the machine can give you the precision you want. Compare prices and see which machines fit your budget.

Use this checklist to match your needs:

Choose a machine that can handle your daily part numbers.

Pick a model that works with all your materials.

Make sure the machine can make threads as exact as you need.

Find out if the machine fits in your workspace.

Check if the machine has safety features for your team.

Look for machines that use less energy and are easy to care for.

You can use the table below to compare important criteria:

| Criteria | What to Look For |

Production Volume | High-speed, automatic models for big jobs; manual or semi-automatic for small jobs. |

Material Compatibility | Machines with adjustable torque and speed for different materials. |

Precision and Accuracy | Digital controls, sensors, and feedback systems for tight tolerances. |

Budget and Cost-Effectiveness | Models with low energy use and easy maintenance to save money over time. |

Now you can make a list of machines that fit your needs. Check each model for the right features. Look at the size and depth of holes you need to tap. Decide if you need to tap through holes or blind holes. Make sure your workpieces are held tight and the tap is sharp and lined up. Check if the machine has torque and depth control. See if you can use the right cutting fluid.

Here is a simple list to help you:

Determine if the hole is through or blind.

Check if the hole is drilled to the correct size.

Ensure the workpiece is rigidly held.

Assess the material and hardness of the workpiece.

Confirm the correct tap design and sizes are available.

Verify the tap is sharp and properly aligned.

Check machine settings for torque control and depth control.

Ensure proper cutting fluid is used.

| Note: You can ask vendors for machine demos or videos. This helps you see how each model works in real life.

You are ready to choose the best tapping machine for your factory. Use a decision-making plan to help you. Think about how the machine can grow with your factory. Make sure it meets safety and environmental rules. Look for new features like IoT and automation. Compare vendors by checking their claims, customer reviews, and support. Make sure the machine has the right certifications.

Here is a table to guide your decision:

Key Factor | Description |

Regulatory Compliance | Meets safety and environmental standards like OSHA, ANSI, and EPA. |

Technological Innovations | Has new features like IoT, AI, and automation for better work. |

Market Dynamics | Fits current trends and helps you stay ahead of competitors. |

You can follow these steps:

Check if the machine can grow with your factory.

Make sure it meets all safety and environmental rules.

Look for advanced features like automation and IoT.

Compare vendors for support and reliability.

| Tip: Always check certifications and ask for third-party audits. This helps you avoid problems later.

You can now pick the machine that matches your needs, fits your budget, and helps your factory work better.

You have a small shop or just started. You need a tapping machine that saves space and money. Electric tabletop models are good for you. These machines fit on a bench and use little energy. You can set them up fast. Manual and semi-automatic choices let you control each step. You can fix parts or make custom jobs easily.

| Tip: Pick a machine with adjustable speed and torque. This helps you work with different materials.

Best Picks for Small-Scale:

Dewalt portable tapping tools

Makita compact electric models

Pneumatic tapping arm machines

You run a factory with regular orders. You need a machine for more parts and many materials. Semi-automatic and multi-directional models are best for you. These machines work faster and give better accuracy. You can switch jobs quickly without long setup.

Model Type | Key Benefit |

Multi-directional models | Tap at many angles |

Servo-driven machines | High precision |

Combination drilling & tapping | Save time |

| Note: Get machines with quick-change tap holders. You finish jobs faster and make fewer mistakes.

You have a big factory. You want fast production and full automation. CNC tapping machines and robotic arms help you reach your goals. These machines run all day with little downtime. You get steady quality and fewer errors.

Recommended Features:

Automatic tool changers

IoT sensors for maintenance

Conveyor systems for part handling

| Alert: Choose machines with strong frames and safety interlocks. You keep your team and your machines safe.

You work in aerospace, electronics, or medical fields. You need high accuracy and special features. Servo-driven and advanced CNC models give you tight tolerances. You tap tiny threads or work with hard metals. Smart sensors and digital controls help you follow strict rules.

| Industry | Machine Feature |

| Aerospace | Servo-driven, high torque |

| Electronics | Automated threading, small taps |

| Medical | Precision CNC, clean design |

| Tip: Ask for machines with certifications for your industry. You follow rules and keep your products safe.

You can make a smart choice for your factory by following a few steps.

Begin where your process runs smoothly and you see clear problems.

Focus on quick results instead of chasing perfect features.

Pick machines that handle changes in your work, not just the best-case plans.

Help your team learn early so everyone uses the system well.

These steps help you get the most value from your tapping machine in 2026.

A tapping machine cuts threads inside holes. You use it to make screw threads in metal or plastic parts. This helps you join pieces together with bolts or screws.

You should check your production volume, materials, and budget. Make a list of your needs. Compare machine features and prices. Ask for a demo if you can.

Yes, many tapping machines work with steel, aluminum, brass, and plastic. You must check the machine’s specs. Some machines let you adjust speed and torque for different materials.

You should check your machine every week. Clean it and look for worn parts. Use smart sensors if your machine has them. Good care helps your machine last longer.

Look for emergency stop buttons, guard sensors, and overload protection. These features keep you and your team safe during work.

The company's products include various full- automatic componentsproduction and processing equipment, full-automatic assemblyequipment, full-automatic production lines, robotics and visionintegration applications, etc